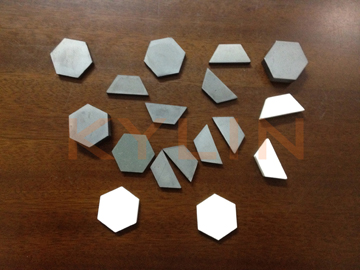

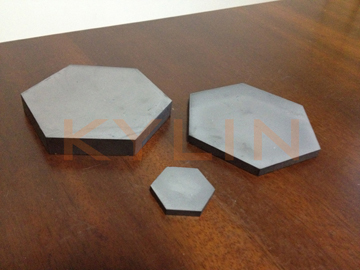

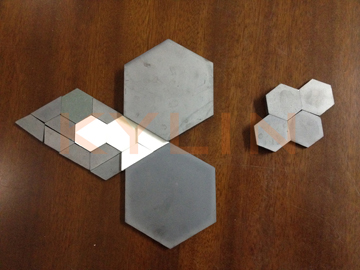

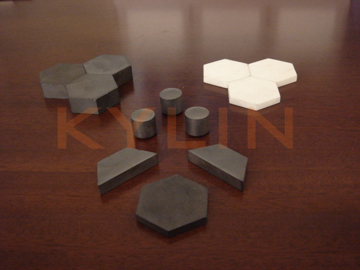

Armor Tile, Ceramic Hexagon Tile, Armor Tiles, Silicon Carbide Tiles, Silicon Carbide Armor

![]()

![]()

![]()

![]()

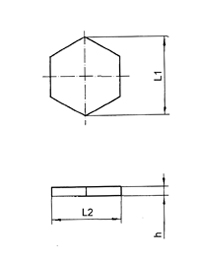

|

Part #

|

L1

|

L2

|

h

|

Materials

|

|

Hex 30*3.5

|

34.64

|

30

|

3.5

|

SSiC

AL2O3 99% AL2O3 99.5%

|

|

Hex 30*3.9

|

34.64

|

30

|

3.9

|

|

|

Hex 30*4

|

34.64

|

30

|

4

|

|

|

Hex 30*4.1

|

34.64

|

30

|

4.1

|

|

|

Hex 30*4.2

|

34.64

|

30

|

4.2

|

|

|

Hex 30*5.1

|

34.64

|

30

|

5.1

|

|

|

Hex 30*6

|

34.64

|

30

|

6

|

|

|

Hex 30*7

|

34.64

|

30

|

7

|

|

|

Hex 30*7.1

|

34.64

|

30

|

7.1

|

|

|

Hex 30*8

|

34.64

|

30

|

8

|

|

|

Hex 30*9.1

|

34.64

|

30

|

9.1

|

|

|

Hex 30*10

|

34.64

|

30

|

10

|

|

|

Hex 30*10.2

|

34.64

|

30

|

10.2

|

|

|

Hex 30*10.5

|

34.64

|

30

|

10.5

|

|

|

Hex 83.14*5

|

96

|

83.14

|

5

|

|

|

Hex 83.14*6

|

96

|

83.14

|

6

|

|

|

Hex 83.14*6.2

|

96

|

83.14

|

6.2

|

|

|

Hex 83.14*6.5

|

96

|

83.14

|

6.5

|

|

|

Hex 83.14*6.7

|

96

|

83.14

|

6.7

|

|

|

Hex 83.14*8

|

96

|

83.14

|

8

|

|

|

Hex 83.14*8.2

|

96

|

83.14

|

8.2

|

|

|

Hex 83.14*10

|

96

|

83.14

|

10

|

|

|

Hex 83.14*10.2

|

96

|

83.14

|

10.2

|

|

|

Hex 83.14*10.5

|

96

|

83.14

|

10.5

|

|

|

Hex 83.14*12

|

96

|

83.14

|

12

|

|

|

Hex 83.14*12.2

|

96

|

83.14

|

12.2

|

|

|

Hex 83.14*15.5

|

96

|

83.14

|

15.5

|

|

|

Hex 83.14*15.8

|

96

|

83.14

|

15.8

|

|

|

Hex 83.14*16

|

96

|

83.14

|

16

|

|

|

Hex 83.14*16.2

|

96

|

83.14

|

16.2

|

|

|

Hex 83.14*18

|

96

|

83.14

|

18

|

|

|

Hex 83.14*18.2

|

96

|

83.14

|

18.2

|

|

|

Hex 83.14*20.2

|

96

|

83.14

|

20.2

|

|

|

Hex 14.2*2.6

|

16.4

|

14.2

|

2.6

|

|

|

Hex 20*3

|

23.09

|

20

|

3

|

|

|

Hex 20*3.5

|

23.09

|

20

|

3.5

|

|

|

Hex 20*13

|

23.09

|

20

|

13

|

|

|

Hex 25*8

|

28.87

|

25

|

8

|

|

|

Hex 25*9

|

28.87

|

25

|

9

|

|

|

Hex 25*10

|

28.87

|

25

|

10

|

|

|

Hex 25*14

|

28.87

|

25

|

14

|

|

|

Hex 27.7*6.2

|

31.99

|

27.7

|

6.2

|

|

Sintered Silicon Carbide (SSiC) Physical Property |

||

| Technical Parameter | Unit | SSiC |

| Hardness | HS | 115 |

| Porosity Rate | % | <0.2 |

| Density | g/cm3 | >3.10 |

| Compressive Strength | MPa | >2500 |

| Fractural Strength | MPa | >380 |

| Coefficient of Heat Expansion | 10-6/°C | 4.2 |

| Content of Sic | % | ≥98 |

| Free Si | % | ≤1 |

| Elastic Modulus | GPa | ≥410 |

| Fracture Toughness | Mpa/m2 | ≥3.42 |

| Temperature | °C | 1400 |

| AL2O3 Ceramic Physical Property | |||

| Technical Parameter | Unit | AL2O3 99% | AL2O3 99.5% |

| Content of Al2O3 | % | 99 | 99.5 |

| Density | g/cm3 | 3.88 | 3.9 |

| Hardness | HRA | 88 | 90 |

| Porosity Rate | % | <0.2 | <0.15 |

| Fractural Strength | Mpa | 310 | 350 |

| Coefficient of Heat Expansion | 10-6/K | 5.3 | 5.2 |

| Modulus of Elasticity | GPa | 300 | 340 |

| Thermal Conductivity | W/M.K | 26.7 | 26 |

Download the 2013 Armor Ceramic Tiles Catalogue.

If you have any questions please contact us at: E-Mail about your composite armor systems.